Ms Sooyung Yang

Dr Terence Love

Lancaster University,

IADE/UNIDCOM,

Abstract

This paper reports doctoral research undertaken at Curtin University of Technology by Ms Yang into the possibilities of integrating the systems of high fashion knitwear design and the programming and operation of computerized wholegarment® knitwear machines to the point of 1st sample prototype. To date, these have been three separate and incommensurate systems. This has resulted in many problems, inefficiencies and loss of creative and competitive advantage. Costs and time to market are high; technicians compromise garment design to make garments easier to program and faster and cheaper to produce; knitwear designers do not understand the creative potential and limitations of the computerized wholegarment® knitting; prototyping new designs is slow and prone to failure; changes to garments are unnecessarily complex and expensive. There are significant cultural, professional, and gender differences between knitwear designers, almost exclusively female and educated in Schools of Art and Design; knitwear technicians, almost exclusively male and educated as engineers; and knitting machine operators, usually female and with limited training. Currently, it is assumed that garments are designed by the knitwear designer, and then the wholegarment® knitting machine is programmed by a knitting technician for production. In reality, getting a garment prototype ready for production requires that there are high levels of collaboration between the three systems. This research has investigated the potential to integrate the three roles into a single unified high fashion wholegarment® knitwear design and prototyping system in which a fashion designer operates the wholegarment® machine directly and undertakes much of the programming role previously undertaken by technicians. The investigation has been undertaken across 8 semi-commercial high fashion knitwear design projects.

Keywords

Fashion knitwear design, prototyping systems, computerised wholegarment® knitting technology

Introduction

This paper describes the systems aspects of research undertaken at Curtin University of Technology with support by the Department of Agriculture and Food Western Australia to improve the integration of wholegarment® knitwear manufacturing (technical programming and knitting machine operation) into the high fashion knitwear design process for production of garment prototypes to 1st sample stage.

Importance of the research

The research is significant in scale because systems for creating ‘fashion’ and for manufacturing clothing provide an important contribution to many countries GDP (Jung, 2004; Kawamura, 2004; KOFOTI, 2008; M.-H. Lee, 2003;

· ‘Cut and sew’ in which flat knitted fabric is produced on computerized knitting machines by the roll and then shapes are cut from it and sewn together as in woven fabric garment production.

· ‘Shaping’, fully-fashioned or integral garment knitting. Shaped flat panels of garment parts are knitted on computerized knitting machines and then assembled together (서울경인스웨터공업협동조합, 2003)

· Computerized wholegarment® knitting systems capable of knitting complete garments without any additional sewing.

There are significant advantages of wholegarment® knitting technology in terms of production (Choi & Powell, 2005). Wholegarment® knitting technology changes the garment supply paradigm in time and cost. It enhances on-demand and simplified garment production processes; eliminates several garment make-up processes; and offers potential for the knitwear industry to transform from being labour-focused to being more technology-oriented. The relatively easy-to-use CAD system has a potential to seed radical innovation in knitwear design processes – the subject of this research.

Factors driving the research

The Shima Seki wholegarment® knitting system was first released in a relatively primitive form in 1995 at ITMA (Shima Seiki Mfg., 2005). This seamless knitting technology has been considered an innovative process and is currently growing in its commercial application around the world (Choi & Powell, 2005). Its main role has been in knitwear for the retail market. By 2003, Shima Seiki had sold more than two thousands wholegarment® knitting systems in Europe and eight hundreds of them in

In spite of its global expansion, Shima Seiki has not tried particularly to support high fashion knitwear designers. It could be expected that after 15 years there would have become established a system for a knitwear designer to use a wholegarment® knitting system for prototype garment making. This has not yet emerged. It is the focus of this research. The wholegarment® technology offers as yet under-developed potential in high fashion knitwear and this is significant as some important fashion countries, e.g. Italy and Japan, have started to move towards high fashion knitwear market to compete with counties such as China and other developing countries in Asia trying to encroach the knitwear market by dint of mass-produced products at low cost (Nam, 2004).

At the same time, however, there has been serious criticism of the interaction between of the wholegarment® technical process and the high fashion knitwear design process (K.H. Soong, personal communication May 26, 2006). The core problem is that for reasons of speed and efficiency and practicality, knitwear technicians typically compromise fashion knitwear designers intentions in order to make a garment easier to program and faster or cheaper to knit. Resolving the tensions between the knitwear designers and wholegarment® technician requires significant to-ing and fro-ing in which neither understands the reasons for the others actions or the language and concepts of the other, and in many cases, these systemically essential interactions do not happen at all. In addition, while wholegarment® machines are relatively easy (though expensive) to obtain and knitwear designers are available to produce designs quickly, the position is bottlenecked by wholegarment® technicians in terms of rapid production of prototypes and the development of program code for knitwear production. In essence, this is the commercial ‘pain’ that this research ameliorates.

By developing a systematically coherent integrated model of high fashion knitwear design process to the point of 1st sample prototype, this research offers a novel innovative basis for resolving all of the above problems in a way that points to significant potential improvement in the high fashion knitwear industry internationally and provides a basis for improving Australia’s competitive position in wool knitwear.

Delimitations

The knitwear design system from fiber/yarn to completion of the prototype ready for production includes subsystems of fiber/yarn design, textile design, fashion design, and the programming system to prepare the code and garment prototypes ready for Shima Seiki’s mass production process. This research has focused on subsystems involving textile design, fashion design, and prototype production to the point of creating the code for the 1st sample and manufacturing a successful 1st sample garment.

Research Approach

Systemically, this is a significantly difficult integration - bridging differences in technical processes, information processes, and content and professional skills in engineering, business, management, craft, and art. It also requires integrating three professions that have to date been separated on grounds of gender and educational pathways. Most knitwear fashion designers are female and educated in Departments of Art and Design. The knitting machine technicians who program the wholegarment® machines are predominately male, operate within an engineering tradition and are usually trained through in-house training schemes at large companies, and recruited straight from school and by training up bright young knitters (knitting machine operators) (Eckert, 1994). Knitting machine operators (knitters) are usually female and have limited training. Knitters typically operate several wholegarment® knitting machines.

This research into the integration of these three systemically incommensurate professional roles was undertaken primarily by empirical investigation and reflective practice and trialled across 8 semi-commercial projects as part of Doctoral and Masters research. One of the authors, Ms Sooyung Yang, is an experienced international knitwear designer and knitwear production manager (12 years). As part of this research project, she undertook residential trainings in

· Working with an Italian designer Bianca Gervasio (2007~2008). This project involved creating knitted fabrics and whole garments featured on Alta Roma/Alta Moda (see http://www.altaroma.it/English/Home.htm, http://www.altaroma.it/luglio2008/Calendario_IT.asp?cmd=view&ID=13http://www.altaroma.it/English/Home.htm, http://www.altaroma.it/luglio2008/Calendario_IT.asp?cmd=view&ID=13, and http://www.agric.wa.gov.au/aboutus/mr/mr061207.htm)

· Design for Comfort (2006) involved creating complex knitted wool fabrics for five Western Australian fashion designers (see http://www.designforcomfort.com.au/http://www.designforcomfort.com.au/)

· Belmont Design Edge workshop (2006) involved production of knitted garments

· Seminar for TAFE students (2006) involving garment production

· Wagin Woolorama Ambassador (2007) involved creating two complete knitted wholegarment® outfits for the (female) ambassador

· Seminar for TAFE students (2007) involving garment production

· Tube sessions with Curtin students exploring wholegarment® knitting technology (2007)

· Designing and creating outfits for dancers at the Dance Performance Night at the Live Stock Updates Conference (2008)

· Tube sessions with Curtin students involved applying wholegarment® knitting technology to their design practices (2008)

Wholegarment® knitting technology

A Shima Seiki computerized flatbed knitting machine with wholegarment® technology, NewSES-183S•WG, comprises two 72" long knitting beds with a machine controller console and a highly sophisticated CAD system comprising a collection of software with different roles. This ‘all-in-one’ design system mainly targets the knitting industry focused on everyday apparel (sweaters, jumpers, scarves etc). The knitting machine is primarily controlled by the Knit Paint program whose main role is as a tool for knitting machine technicians to program the wholegarment® knitting machine although Shima Seiki’s marketing department claims that it is for knitwear designers (Claudia Eckert, 2001). The Shima Seiki CAD system also includes software specific to spinners, designers, knitters, contract knitters, textile designers, embroiders, and printing artists (Shima Seiki Mfg., 2008a). The software, ‘Design’ (until recently called ‘Paint’) is intended as the main program for designers to use. Shima Seiki claims their software system as superior to other apparel CAD system. From experience, this is not obviously true and in many cases, the Shima Seiki system seems unduly complicated particularly in its workflow compared to apparel CAD software form some other manufacturers. Without a well-defined workflow and practical exemplars of efficient ways of prototype making, knitwear designers are overly dependent on knitting machine technicians and knitting machine operators. In effect, knitwear designers are blocked by the hurdle of managing the complexity of the wholegarment® design software. This requires training and it appears that very few knitwear designers attend the long-term overseas residential trainings on wholegarment® programming made available by the manufacturers. One aspect of this research is to identify what aspects of the knitting machine technician’s programming training are useful to a knitwear designer. To this end, Ms Yang attended a series of 3 residential trainings in wholegarment® programming in part funded by Shima Seiki and in part by herself.

Systemic focus of the research

Knitwear design and production typically involves three main groups of expertise: knitwear designers, knitting machine technicians and knitting machine operators (knitters). Although their work systems require overlap and interdependence to produce successful outcomes, there is usually little communication between the three groups except for a hierarchical ‘passing down the line’ of garment specification sheets and manufacturing instructions. This is a situation that echoes the now widely criticized ‘over the wall’ and ‘waterfall’ methods that typically results in slow and problematic design processes and compromised or sub-optimal outcomes (Mascitelli, 2006).

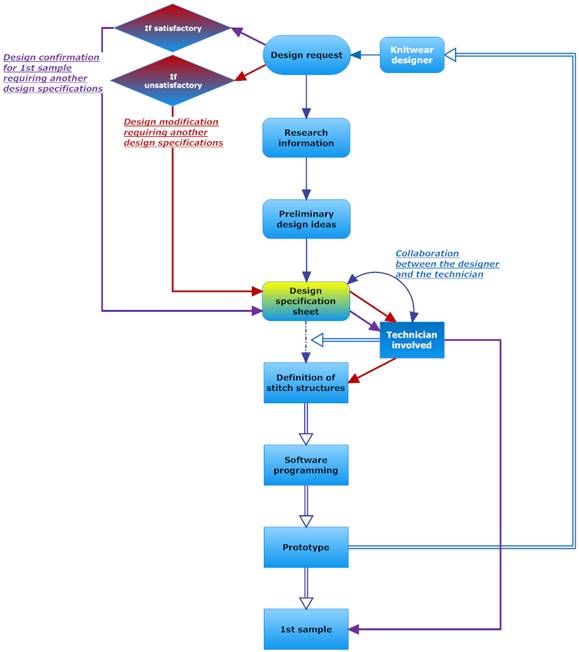

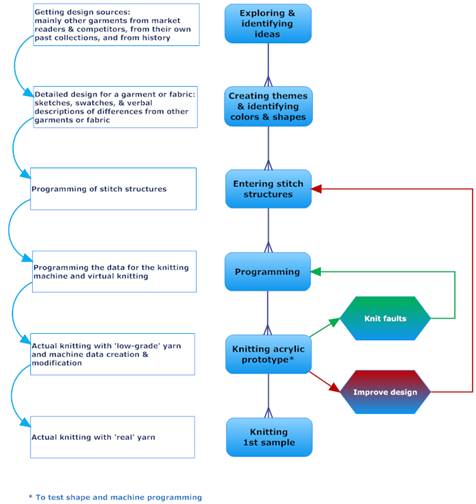

Figure 1 below shows a typical generic non-wholegarment® knitwear design process to the point of production of the 1st sample prototype. This 1st sample prototype is a garment that is produced using the correct yarns. It is only at this point, that the prototype can be fully checked to give confidence that what will be knitted is likely to be what was designed. The steps in the process may have a slightly different order company to company and some steps added or deleted depending on the types of garment a company is manufacturing.

Figure 1: Conventional workflow of non-wholegarment® knitwear design process

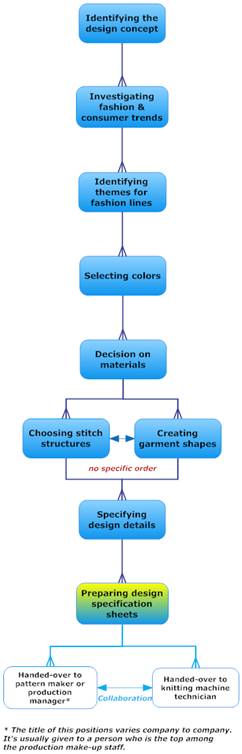

The design system for knitwear is larger and more complex than for woven textile fashion design in two respects. In knitwear design, the colours, stitch structures that form the texture and the garment shape are created simultaneously (see Figure 2 below). Secondly, unlike fashion design, best quality outcomes in knitwear design depend on intensive collaboration between the knitwear designer, knitting machine technician and knitting machine operator when preparing the design specification sheet for the 1st sample garment.

Figure 2: Knitwear designers’ activities up to design specification sheet handover

The quality of 1st sample outcome depends on good collaboration to guarantee the design specifications sheet, prototype and 1st sample are as close as possible to the knitwear designer’s original intention. This contrasts with most other forms of fashion design in which designers simply make the first sample themselves by hand via a combination of draping and flat patternmaking in paper or cardboard (Stecker, 1996).

In current knitwear design systems, a ‘communication bottleneck’ compromises this essential collaboration (Claudia Eckert, 2001). Conventionally, after the fashion knitwear designer has completed the functional steps in Fig 1, they then hand over a design specification sheet for the garment to the knitting machine technician who decides what type of knitting machine to use and programs the knitting machine to produce the first prototype.

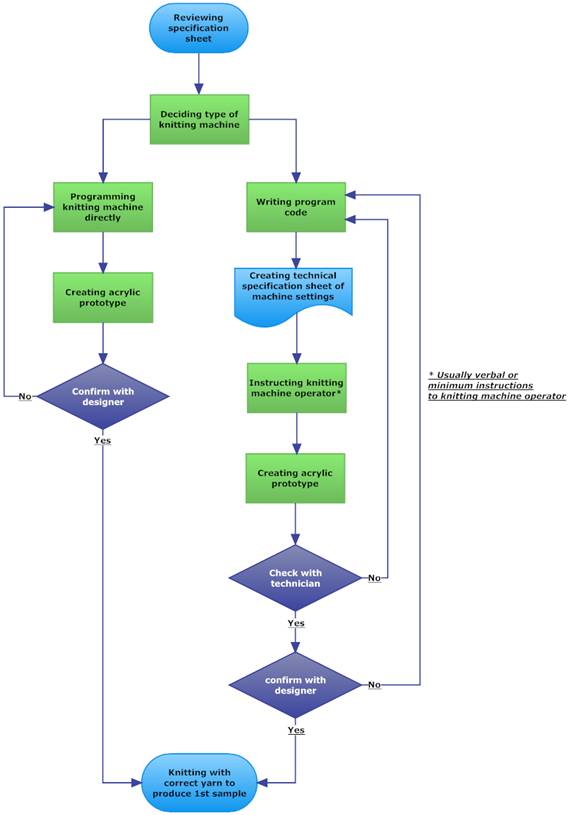

The first prototype is created with relatively cheap acrylic yarn (see Figure 3) to check mainly its feasibility on the machine and knitting quality. The technician may need to work on the CAD system to program the knit data if the design requires the computerized knitting system. He may operate the computerized knitting machine by himself or have a knitting machine operator run it. When the programming is functioning satisfactorily, the 1st sample garment is knitted using the correct yarns.

Figure 3 shows the system of the knitting machine technician after they receive the design specification sheet. In the typically ‘over the wall’ approach, the system in Figure 3 follows directly from that shown in Figure 2. After deciding which knitting machine to be used, the technician, then, prepares a technical specification sheet for knitting machine operators. The knitting machine operators are the individuals who physically operate the industrial knitting machines, which can be wholly manual, half-manual, or automatic (flat-bed and wholegarment®). Knitting machine operators normally look after a group of knitting machines and like to see their knitting machine running as much of the time as possible. They are usually given verbal instructions, and minimum instructions are given if written. From experience, knitting machine operators prefer to avoid working on prototypes and 1st samples because these demand frequent machine stops due to programming errors or faulty machine setting data.

Figure 3: Knitting machine technician activities after design specification sheet

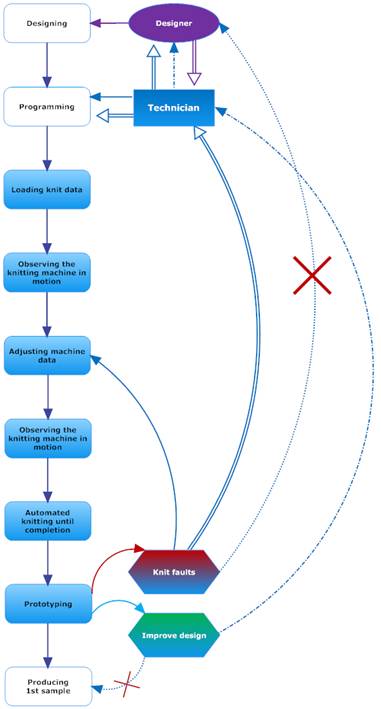

The conventional system wholegarment® knitwear system to the point of production of 1st sample is complex and combines the activities of knitwear designer, knitting machine technician and knitting machine operator as shown in Figure 4.

Figure 4: Conventional knitwear prototyping system involving knitwear designer, knitting machine technician and knitting machine operator

Research Outcomes: A New Integrated Prototyping System for Wholegarment® Knitwear Design

To recap, any prototyping system for knitted fashion garments must result in a sample garment like any other fashion garment design process. As explained earlier, knitwear design has additional complications over conventional cut fabric procedure that process has to also include the design the knitted fabric and the process for creating that fabric (in the case of wholegarment® computerized knitting this consists of a computer program to produce the ‘1st sample’ garment). Conventionally, this process is problematically split between two persons: knitwear designer and knitting machine technician via an ‘over the wall’ or ‘waterfall’ design process in which the knitwear designer hands over a design specification to the knitting machine technician. The problem is that the two activities are not independent. Many apparently ‘knittable’ fabrics are not, and the creative potential of the wholegarment® knitting machine is neither fully explored nor represented in the software intended to be the sole point of access of the knitwear designer. In short, there is need for high levels of collaboration between high fashion knitwear designer and knitting machine technician. Blocking this possibility are several factors as described earlier in terms of the differing cultures and work pressures underlying each of these roles. There are insufficient knitting machine technicians; they are expensive to employ; their training and culture acts against them being collaborative partners in the creative aspects of knitwear design; and the weight of focus of their work is towards maximizing production and the management of the knitters (i.e. the knitting machine operators).

An alternative is for the prototyping system of high fashion knitwear designers to incorporate some of the technical roles of the knitting machine technician and knitting machine operator. The natural breakpoint is at the culmination of the creation of the 1st sample. At this point, the knitwear designer can verify that the proposed garment is knittable; can confirm that the knitting software produces the garment that was intended; can check the yarn and fabric performance and garment shape (the 1st sample is made in the yarns that the final garment will be produced, as distinct from the earlier prototypes that are made in relatively cheap acrylic yarn during the stages where the software is being modified to enable knit-ability).

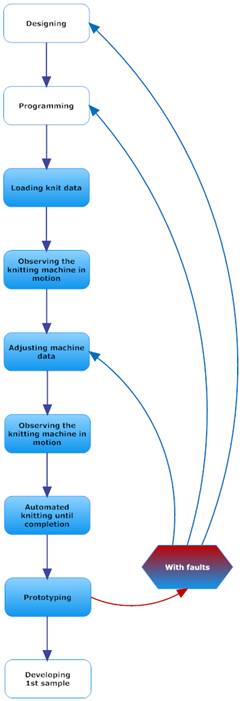

In the course of this research, Ms Yang, identified ways for knitwear designers to undertake sufficient of the roles of the knitting machine technician and knitting machine operator to undertake all of the prototyping of new fashion knitwear garments to the 1st sample stage. Figure 5 below shows the practical details of the workflow system Ms Yang identified for 1st sample production using the Shima Seiki wholegarment® knitting system.

Figure 5: Workflow for an integrated fashion knitwear prototype production to 1st sample stage undertaken only by the knitwear designer using Shima Seiki wholegarment® knitting system

The designer as an individual undertakes the knitwear design, programs the knitting machine and operates it. As a result, the system is simpler and better integrated than the conventional 1st sample design, prototype and production process. Figure 6 below provides a simplified generic model of this process.

Figure 6: New integrated wholegarment® prototyping system

An important and not necessarily obvious benefit from the whole prototyping system being undertaken by the knitwear designer is that their complete attention is given to all things related to the prototyping production. This contrasts with the conventional approach, in which the knitting machine technician and knitting machine operators cannot pay that intensity of attention to what is for them an incidental and secondary part of their work. In addition even if a knitting machine operator wished to pay more attention, it is mentally and physically impossible because they are managing many machines and the noise from groups of computerized knitting machines seriously affects mental performance. In addition, knitting machine operators do not have the authority to adjust the program independently of instructions from the knitting machine managers or technicians. This, with the lack of a direct feedback communication channel to the knitwear designer means a significant loss of information that could beneficially shape a design. Sometimes, designs that might cause real problem in production could be corrected at early stages of the process.

Where prototyping is undertaken on knitting machines in industry setting that are normally used for production, there are time and economy pressures and constraints. The integrated wholegarment® knitwear prototyping approach described above removes time restraints due to unconnected production factors. This means a high fashion knitwear designer can develop the prototype until satisfied with the design.

Conclusions

This paper has described systems research into improving knitwear design practices in the fashion knitwear industry in the use of wholegarment®’ knitting technology for prototyping fashion knitwear designs for production. In particular, these systems analyses have focused on changes in practice and improvements in design process intended to bridge the up to now incommensurably different systems of knitwear designers, knitting machine technicians and knitting machine operators in the garment prototyping system to 1st sample stage.

The research demonstrated it is possible to integrate these three systems to be undertaken by a professional knitwear designer with additional training. This offers significant benefits in knitwear prototype production and testing, reduction in time to market, reduction in design costs, and potential increase in the creative solution space for high fashion knitwear design.

The research points to the need for a rethinking of the education of knitwear designers to include a new approach to wholegarment® prototyping skills. It also points to two new opportunities in the technical realm for developments to support this integration of professional services. These are:

· The development of an interface for the wholegarment® development that is more culturally, aesthetically matched with the skills and ways of working of creative knitwear designers (this aligns with the findings and research direction of Claudia Eckert and her colleagues (Claudia Eckert, 2001; C. M. Eckert, Cross, & Johnson, 2000)

· New software to enable creative/high fashion knitwear designers to program computerized wholegarment® knitting machines at a stitch-by-stitch level. This is different to the current approaches for semi-automatic production of program code currently provided by wholegarment® knitting machine manufacturers (see, for example, the Shima Seiki SES system). An example of this would be the ability to automatically transfer colour vector diagrams direct into the knitting machine code.

Acknowledgements

The research was undertaken using a Shima Seiki NewSES-183S·WG, WHOLEGARMENT® knitting machine with interactive SDS®-ONE graphics system made available for the research by the Department of Agriculture and Food Western Australia (DAFWA). We give thanks to Dr. John Stanton (Associate Supervisor) and Dr. Mark Dolling and their staff at DAFWA. The semi-commercial knitwear design projects undertaken as part of this research primarily used 2 ends of 2/30 Cashwool®, known as the best suitable commercial yarn for wholegarment® knitting. Wool yarns and other consumables such as knitting machine parts and knitting needles, machine maintenance necessities, and supplementary items were provided by the Wooldesk at DAFWA. Initially the research was undertaken under the guidance of Dr. Suzette Worden, who with Senior Lecturer Anne Farren has provided guidance and management in the external aspects of several of the practical projects. The authors thank all of these individuals and organizations for their support and participation. The remaining aspects of this research were funded by one of the authors, Ms Sooyung Yang, as part of her Masters and Doctoral research undertaken at Curtin University of Technology.

References

Black, S. (2002). Knitwear in Fashion.

Calasibetta, C. M. (1988). Fairchild's dictionary of fashion (2nd ed.).

Choi, W. P. S., & Powell, N. (2005). Three Dimensional Seamless Garment Knitting on V-bed Flat Knitting Machines. Journal of Textile and Apparel, Technology and Management, 4(3).

Dale, J. S. S. O. (1986). Art to wear (1st ed.).

Eckert, C. (2001). The Communication Bottleneck in Knitwear Design: Analysis and Computing Solutions. Computer Supported Cooperative Work (CSCW), V10(1), 29-74.

Eckert, C., & Stacey, M. (1994). CAD Systems and the division of labour in knitwear design [Electronic Version]. Women, Work and Computerization: Breaking Old Boundaries - Building New Forms, 409-422. Retrieved 25/08/2008 from http://www.fibre2fashion.com/industry-article/10/932/cad-systems-and-the-division1.asp.

Eckert, C. M., Cross, N., & Johnson, J. H. (2000). Intelligent support for communication in design teams: garment shape specifications in the knitwear industry. Design Studies, 21(1), 99-112.

Harris, J. (1993). Textiles: 5000 Years: Harry N. Abrams.

Hatch, K. L. (1993). Textile science. Minneapolis/Saint Paul: West Pub.

Jung, J.-H. (2004). A Study of Wholegarment Fashion Design. Unpublished Master's,

Kawamura, Y. (2004). The Japanese revolution in

KOFOTI. (2008). Information. The past & present of textile industries Retrieved 22/09, 2008, from http://www.kofoti.or.kr/info/textile01.php

Lee, K. -h., Kim, H.-j., Kim, Y.-j., Kim, Y.-k., Noh, K.-h., Oh, H.-s., et al. (2002). The conceptualisation of fashion design (패션디자인 발상). 서울: 교문사.

Lee, M.-H. (2003). (A) study on the Design inclination of modern Women’s knit - Analysing Sonia Rykiel`s collections. Unpublished Master's,

Mascitelli, R. (2006). The Lean Product Development Guidebook: Everything your design team needs to know to improve efficiency and slash time-to-market.

Park, Y. -

Pattern (sewing). (2008, 28/08). Retrieved 21/09, 2008, from http://en.wikipedia.org/wiki/Pattern_(sewing)

Shima Seiki Mfg., L. (2008a, 17/09). Apparel Design System. SDS-ONE ® Retrieved 20/09, 2008, from http://www.shimaseiki.co.jp/product_cge/sdsone_rd2e.pdf

Shima Seiki Mfg., L. (2008b). SDS-ONE Paint HELP (A-58).

Shima Seiki Mfg., L. (Ed.). (2005). Shima Seiki Corporate Profile.

Spencer, D. J., & Knovel (Firm). (2001). Knitting technology

A comprehensive handbook and practical guide (3rd ed.).

Stanfield, L., &

Stecker, P. (1996). The Fashion Design Manual.

Wilson, A. (2008). The Seamless Shift [Electronic Version]. Journal for

서울경인스웨터공업협동조합. (2003). 스웨터기술교본. 서울: 한국섬유산업연합회.

COPYRIGHT

S. Yang & T. Love ©2008. The author/s assign